Views: 43 Author: Site Editor Publish Time: 2022-05-10 Origin: Site

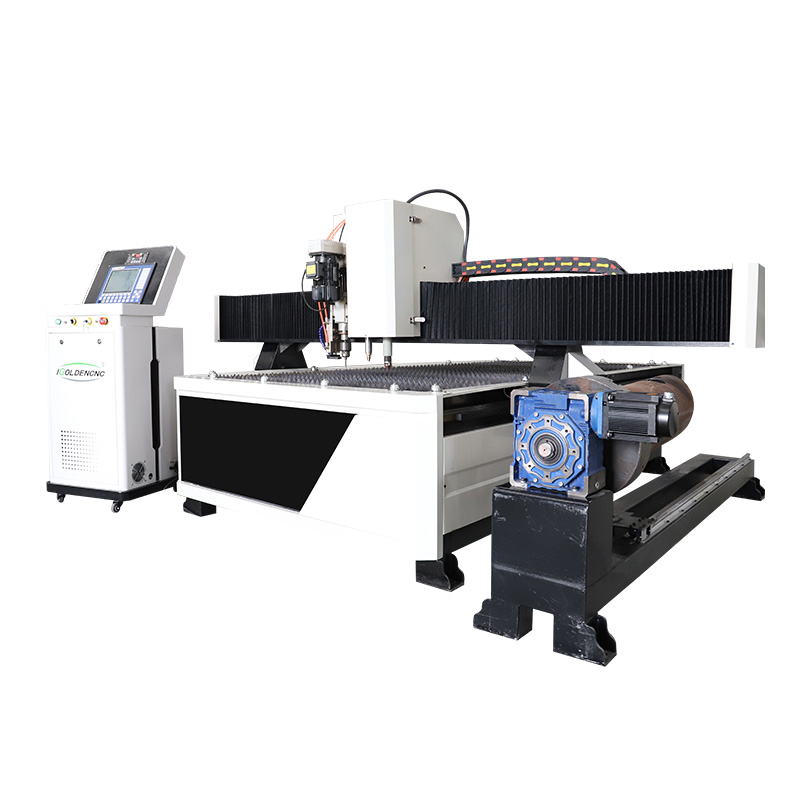

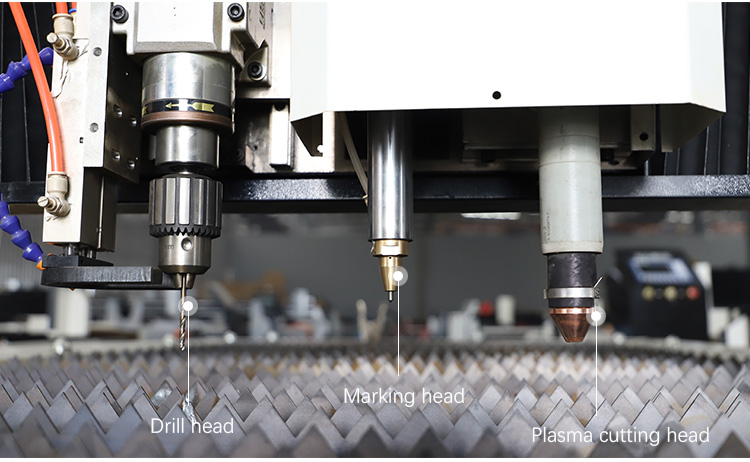

The cnc plasma router is mainly used for The plasma cutting machine is configured with plasma power with 65A, 80A,100A,125A,160A, and 200A according to the thickness of the steel material. The plasma cutting machine is with high speed and good quality cutting performance.

How to make appropriate daily maintenance for a cnc plasma cutter? Proper daily care is beneficial to prolong the machine's service life and maintain good machining accuracy. If you can follow the daily checklist below, your plasma cnc tables would be well maintained.

• Before turning on the machine, check whether there is any air leakage in the connecting parts of the gas system, plasma source, and cutting torch. Once found, it must be eliminated.

• Before cutting, you must check whether the cutting nozzle and electrode used are consistent with the plasma power setting and the thickness of the steel plate being cut. The current intensity should be within 95% of the working current of the nozzle. For example, the current power of a 100A nozzle should be set at 95A. The cutting nozzle cannot be used beyond the range.

• Check whether the gas pressure is within the allowable range. Whether the gas is clean, check whether the air compressor is running normally, check the air filter device frequently, and replace the accessories in time.

• After replacing the cutting consumables, or when the cnc plasma router has not been used for a long time, we need to turn the current knob to the gas test position. Or manually open the solenoid valves to remove water, gas, and impurities in the hoses and the cutting torch.

• We should clean and oil the X/Y linear guideways regularly.

• When the operator rests or leaves the machine for a long time, the power and air supply should be cut off.

• After the auto cutting is complete, you must wait for a while and then turn off the power after the electrical cabinet, and the plasma source is sufficiently cooled.

• Regularly clean and oil the racks.

• Lubricate the lifting mechanism, such as ball bearings, lead screws, and linear guide sliders, regularly.

• Regularly clean the slag under the cutting table and wipe the ash layer on the surface of the cnc plasma cutting equipment.

• Regularly check whether the machine's upper and lower limit switches are in good condition and replace the failed switches in time.

• Use a dry brush to clean the dust layer on the side filter of the cabinet once a month.

• Every three months, check whether the cables in all parts of the machine are worn or not.

• Every year, check whether the fastening bolts are loose.

• Suppose the machine is not used for a long time. In that case, we should conduct the dry run regularly, preferably 1-2 times a week, and 1 hour each time, to use the machine's heat to reduce the humidity in the device and make the electronic components not get wet.

• Check whether the terminals are well fixed once a year. The wiring terminals may become loose due to long-term operation and vibration. The flexible wiring terminals may be damaged by heat during the process.

A cnc plasma router also requires a drive system, consisting of drive amplifiers, motors, encoders, and cables. There will be at least two motors, one for the X-axis and one for the Y-axis. There is a drive amplifier for each motor, which takes a low-power signal from the CNC and turns it into a higher-powered signal to move the motor. Each axis has a feedback mechanism, usually an encoder, which creates a digital signal indicating how far the axis has moved. Cables take the power from the amplifier to the motor, and carry the position signals from the encoder back to the CNC.

Most companies and hobbyists invest in CNC plasma cutters because they offer far more control than a normal plasma cutter.

Rather than being handheld, a CNC plasma cutter is moved around by a computer. Thus, the system:

Is great for repetitive cuts

Reduces waste

Takes less time once the design is created

Is more precise

cnc plasma cutter art

Image: northenridgebursery.com

No matter how skilled an operator of a handheld plasma cutter is, they are only human and can easily slip or introduce an error into the work. The errors can only be introduced in the programming side of a CNC machine.

So the setup of the design in a CNC plasma cutter is the most important step. If you have the programming right, you can get extremely precise shapes quickly and easily and repeat them over and over again. This is perfect for production pieces or even sculptures that have a lot of detail.

Most of the time is spent creating the design in the computer. Of course, the CNC can be running a different program during this stage, so there isn’t any wasted time. The machine can also cut far quicker than most handheld plasma cutters and beat out even the quickest person.