Views: 12 Author: Site Editor Publish Time: 2022-11-29 Origin: Site

Significantly boosts metal fabricators’ efficiency in handling complex metal tasks using our sheet and tube fiber laser cutter. By integrating sheet cutting and tube cutting in a single laser, you benefit from laser cutting with minimum investment and space but outstanding performance.

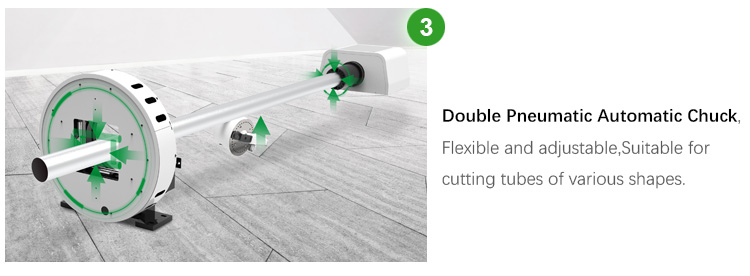

The dual-use fiber laser cutting machine can realize the cutting of two different materials on the same equipment. It can cut both metal plates and tubes (including square tubes, round tubes, channel steel, angle steel, etc.). One machine with multiple functions, high cost performance, professional pipe cutting control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises.

The dual function fiber laser cutting machine enables the cutting of metal sheets and tubes on the same machine. Ultra-large format, capable of cutting sheet width not exceeding 2000mm×6000mm, cutting pipe length 6m, pipe diameter 20mm~300mm.

Gear rack drive system, professional cutting CNC system, easy to operate and maintain. In addition, the rigorous assembly process ensures high-precision and stable operation of the CNC laser cutting machine. The fiber laser cutting machine uses imported high-end accessories to provide users with powerful cutting ability and efficiency. It is the best choice for economical sheet and tube processing.

Handle sheet and tube cutting with a single laser

Reliable with no collision or micro-joints

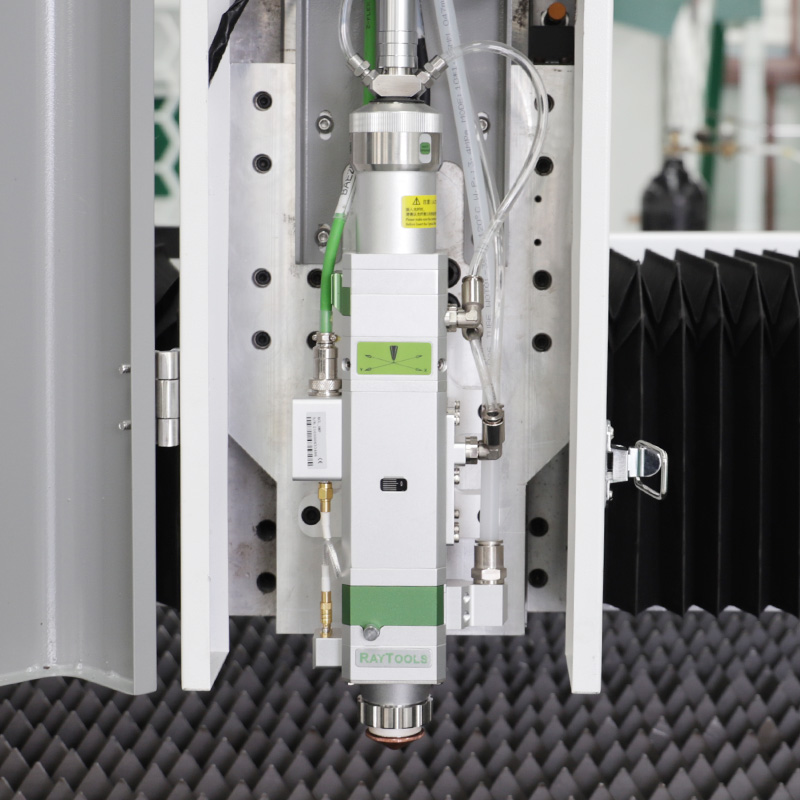

When manufacturing parts, your machine intelligently takes parts tipping over into account. This means you can carry out production reliably – without collisions or micro-joints. With the smart anti-collision function, the laser cutting head will automatically jump over or bypass the tilted cut-offs and move smoothly to the next workplace, avoiding collision and effectively reducing the damage rate of laser heads. This minimizes non-productive times and makes your machine permanently productive.

Favored by fabricators of sheet metal, fitness equipment, electrical cabinet, elevator and escalator, kitchen appliance, metal doors and windows, this sheet and tube laser cutting machine effortlessly cuts carbon steel plate, stainless steel plate, cold-rolled plate, electrolytic plate, aluminum alloy plate, galvanized plate as well as various types of tubes including square tubes, round tubes, rectangular tubes, oval tubes, D-shaped tubes, and hexagonal tubes.

1.The metal laser cutter's controller with a touch screen operating system:

Fiber laser controller installed on the computer (English version of Windows XP system);

Ytterbium laser cutting system, automatic optimized cutting path calculation, industrial computer installed software;

Touch screen operation system to control the laser head (adjust the distance between the laser head and metal material); wireless control handle can control the laser cutting head movement trajectory.

2.The metal laser cutter with 3HP high-power water chillers: adopts water cooling method to keep the laser head always work in constant temperature(plus or minus 5 degrees), to ensure the the stability and fast operation of the laser.

3.The metal laser cutter with Raycus 1000W (IPG1000W) fiber laser generator:photoelectric conversion rate is high, high beam quality, work life of more than 100,000 hours, no maintenance costs.

4.Universal ball screw and jagged shaped working platform, loading metal material fast and keeping stable feeding work. jagged platform fixing strip can fix material to reduce the spark splash when cutting.

5.The cutting machine is adopted Japan's Panasonic servo motor and drive: improve the cutting speed and stability. Positioning accuracy: ≤ ± 0.05mm; maximum moving speed 90m / min, maximum effective cutting area 1500 * 3000mm. The servo system has good dynamic response acceleration characteristics for smooth operation, reliable, no maintenance.

6.Self-service refueling, alarm system, smoke device: Laser cutting machine tracks can automatically be refueled, always ensure track lubrication. laser cutting machine alarm system to remind the situation of the role of the machine. Smoke device can extract the smoke in the cutting process, to protect the working environment.

7.Rotary aids: the unique design with rotary auxiliaries can solve the technical problems for cutting pipe.

content is empty!