Views: 7 Author: Site Editor Publish Time: 2022-06-28 Origin: Site

What is Plasma?

To understand how a plasma cutter works, it’s important to know what plasma is. There are three fundamental forms of matter – solid, liquid, and gas. But, there is a fourth one as well, which is plasma. In daily lives, plasma can encounter in several products such as fluorescent lamps, televisions, and of course plasma cutters. Plasma is often called as an ionized gas because it can be generated by heating a natural gas to extreme temperatures or subjecting it to an electromagnetic field where the ionized gas element becomes electrically conductive. As a result, Steel plate plasma cutting machine can pass through metals such as brass, aluminum, steel, and copper with no resistance.

In the use of the present laser precision cutting, compared with the traditional processing methods, now the laser precision cutting has many prominent points. For example, in the use of laser cutting can be a narrow incision, there is almost no residual residue, only a small heat affected zone, while the process of processing no noisy sound, the material used above can save the traditional processing methods of material $number. In particular, cutting printed circuit board PCB in the surface of the installation template, the use of traditional processing methods, because the limit size of the processing is not less than the thickness of the plate, and processing because of its complex operation, processing cycle is very long, but also pollute the environment, it is difficult to adapt to the current processing needs The use of the current laser processing, not only to avoid the shortcomings of these traditional processing methods, but also to the finished product template can be processed.

In addition to daily maintenance, in order to reduce the wear and accidental damage of the Plasma Cut Plates, it is necessary for the staff to perform correct and safe operation, which is not only responsible for the equipment, but also for the personal safety of the staff. The way is as follows:

1. Operators must wear protective masks, welding gloves, hats, filter dust masks and soundproof earmuffs. Personnel without protective goggles are strictly prohibited from directly observing the plasma arc, and bare skin is strictly prohibited from approaching the plasma arc.

2. When cutting, the operator should stand on the upper wind to operate. The air can be drawn from the lower part of the workbench, and the open area on the workbench should be reduced.

3. When cutting, when the no-load voltage is too high, check the electrical grounding, zero connection and the insulation of the torch handle, insulate the worktable from the ground, or install a no-load circuit breaker in the electrical control system.

4. The high-frequency generator should be equipped with a shielding shield, and the high-frequency circuit should be cut off immediately after the high-frequency arc is used.

5. The use of thorium and tungsten electrodes should comply with the safety operation regulations of relevant documents.

6. The cutting operation and cooperating personnel must wear labor protection equipment as required. Safety measures must be taken to prevent accidents such as electric shock, falling from heights, gas poisoning and fire.

7. The electric welding machine used on site shall be equipped with a machine shed to prevent rain, moisture and sun, and shall be equipped with corresponding fire fighting equipment.

8. Safety belts must be fastened when welding or cutting at high altitudes. Fire prevention measures should be taken around and below the welding and cutting, and special personnel should be supervised.

An excerpt from industries and possible areas of application for ZINSER plasma cutting systems:

Construction industry

Energy industry

Mechanical engineering

Steel industry

Ventilation construction

Metalworking

Vehicle construction

Shipbuilding

Advantages of Plasma cutting system

- Able to cut all conductive materials. Flame cutting, though also suitable for cutting thick metals, is limited to ferrous metals only.

- Great quality for thickness up to 50 mm.

- Maximum thickness up to 150 mm.

- Comparatively cheap for medium thickness cuts.

- Best way to cut medium thickness stainless steel and aluminum.

- CNC machines are available to provide high precision and repeatability.

- Can cut in water, resulting in smaller HAZ. Also reduces noise levels.

- Smaller cutting kerf compared to flame cutting.

- Quicker cutting speed than oxyfuel.

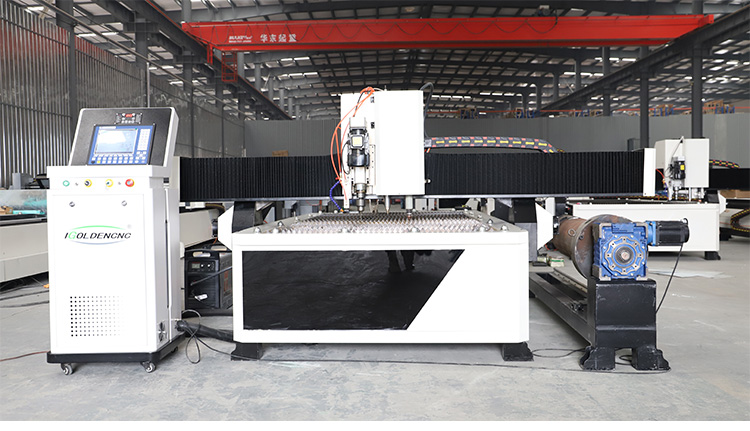

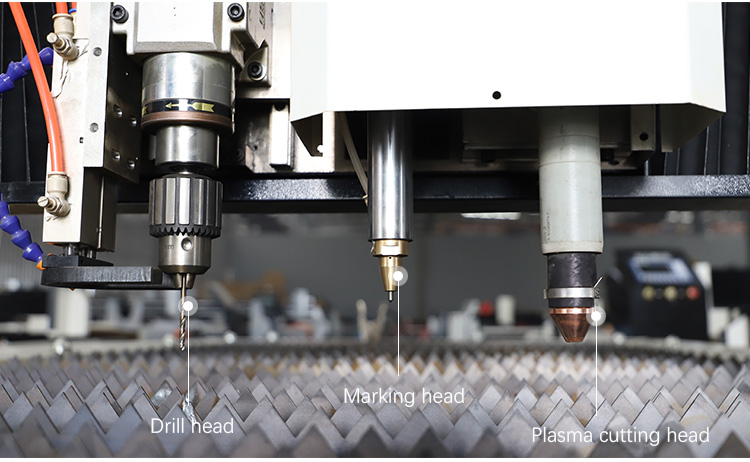

Steel plate plasma cutting machine is a process that is used to cut steel and other metals of different thickness using a plasma torch. In this process, an inert gas is blown at high speed out of a nozzle. At the same time, an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is extremely hot to melt the metal being cut and moves quickly to blow molten metal away from the cut.

Steel plate plasma cutting machine is important and vital when it comes to cutting certain metals and materials. Plasma cutting burns through thicker material than laser cutting and water jet cutting. Depending on the electrical current capacity and the type of metal, plasma cut metal can range from .125” to 2” thick. While we specialize mostly in burning heavy steel parts, choosing the plasma cutting services at Steel plate is more economical than laser or waterjet cut metal while also providing the highest quality end product.