Views: 6 Author: Site Editor Publish Time: 2022-06-08 Origin: Site

We must be familiar with the traditional 5 axis CNC machine for stone, bridge saw is the popular tool in stone fabricator. However, with the industrial upgrading, enterprises to the degree of automation requirements, the traditional bridge cutting machine has been unable to meet the requirements of modern processing. In order to meet the needs of diversified processing market, Yongda has tailor-made a CNC bridge cutting machine for each major stone enterprise. The machine has powerful function, multi-purpose, small footprint, low energy consumption, simple operation, precise processing, fast and convenient conversion of different functions. One device meets multiple need.

5 axis CNC machine for stone, also called Stone cutting machine, is a kind of multi-knife multi-stage stone cutting machine composed of cutting knife set, stone conveying table, positioning guide plate and frame.

1. The cutting knife group is placed on the upper part of the stone conveying table and placed on the frame, and the positioning guide plate is fixed between the cutting knife groups; the cutting knife group is composed of a motor, a belt, a cutter wheel shaft, and a cutting tool, and the cutting tool is fixed on the cutter wheel shaft. This kind of stone cutting machine can cut stones with different depths respectively, and can process stones less than 1m3, which can turn waste into treasure, greatly save stone resources, and also help protect the environment. Various types of stones can be mechanically cut, and the processing efficiency is high. In addition, the effective use of small stones makes the production cost lower.

2. In the process of mechanical processing, the common methods of plate cutting include manual cutting, semi-automatic cutting machine cutting and CNC cutting machine cutting. Manual cutting is flexible and convenient, but manual cutting has poor quality, large dimensional errors, large material waste, large follow-up processing workload, harsh working conditions and low production efficiency. Among the semi-automatic cutting machines, the profiling cutting machine has good quality of cutting workpieces. Because it uses a cutting die, it is not suitable for single-piece, small-batch and large-scale cutting. Although other types of semi-automatic cutting machines reduce the labor intensity of workers, their functions are simple and are only suitable for cutting some more regular-shaped parts. Compared with manual and semi-automatic cutting methods, CNC cutting can effectively improve the efficiency and cutting quality of plate cutting, and reduce the labor intensity of the operator. With the development of the modern machinery industry, the requirements for work efficiency and product quality of sheet metal cutting have also increased at the same time. Therefore, the market potential of CNC cutting machines is still great, and the market prospects are relatively optimistic.

3. Judging from the application of various CNC cutting machines, the technical level and overall performance of the domestically produced CNC cutting machines have made gratifying progress, gradually catching up with the international advanced level, meeting the needs of users, and further improving Improved market competitiveness. Some domestic CNC plasma cutting products have formed their own unique characteristics in many aspects, achieving "automation, multi-function and high reliability". In some respects, the technical performance of the product even exceeds that of foreign products. Improving the production efficiency and cutting quality of the CNC cutting machine, reducing the cost of production and use, improving the automation level and system stability of the whole machine, and improving the system functions have become the direction of its technological development.

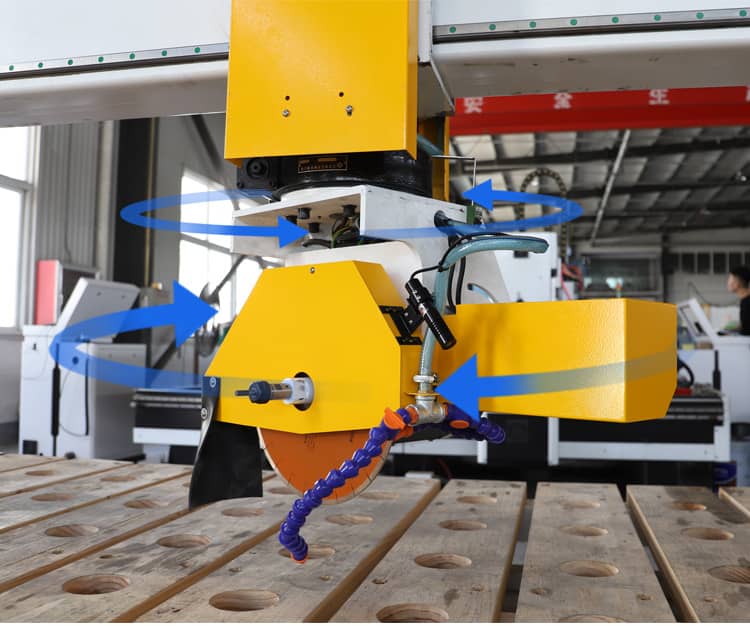

1, PLC control system, input parameter through hunman-machine interact interface(cutting size,moveing speed etc.),then automatic cutting.

2, Use infrared to guide work-piece location.

3, Seperated style, basement can be concrete foundation or steel frame.

4, Individual worktable, 90°rotation,85°titling.

5, Max. diameter disk 400mm (ZDCQ-600 model can be 600mm)

6, Max.Work size :3200×3200×65(mm)。

7, Cutting head lifting by single hydraulic cylinder drive,double slide double dovetail guide structure。

8, Portrait slicing, by encoder or magnetic grid caculation.

Bridge saw machine table.

A table is use to load and unload stone material while machine is working. In China, all tables are designed to be 85 degree stand up and down to load and unload slab. Besides, we can also make table rotation horizontal in different such as 45°,90°,180°and 360°. All of these actions are full automatic.

Applicable industry & material

Applicable industry: sintered stone application industry, fabricated building materials industry, home decoration materials industry, cutting marble, artificial stone, quartz stone and other materials.

Applicable material: sintered stone, ceramic plate, quartz stone, marble, etc.