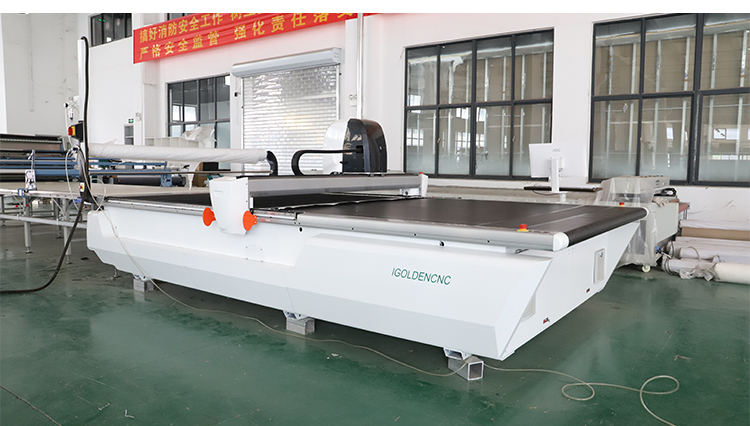

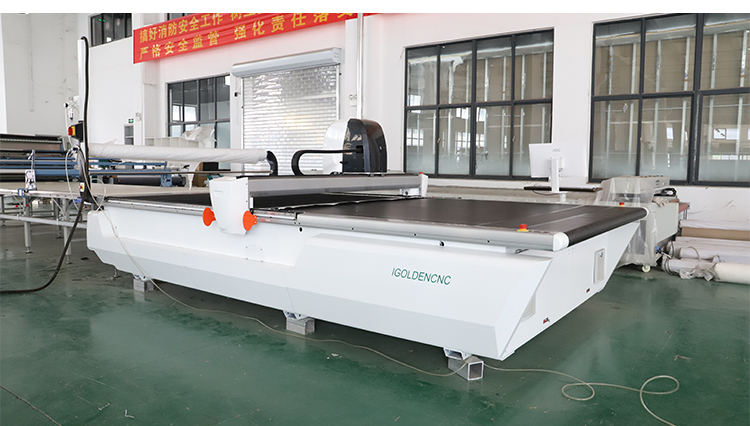

iGK-VA

iGOLDENCNC

iGK-VA

| Availability: | |

|---|---|

Multi-layer fabric cutting machine is more suitable for massive orders of big shape patterns like soft furniture and garment, while the die cutting machine can better deal with bulk orders of small shape patterns like shoe uppers, hats, and gloves.

When using industrial fabric cutting machines, you want your device to produce as much plain fabric per day as possible. The higher the production, the higher the efficiency.

However, the output of this depends on the type of industrial fabric cutting machine.

In this aspect, the multi-layer fabric cutting machine and the die cutting machine have a higher production capacity due to the multi-layer cutting method.

| Product number | 1725 | 2030 | 2330 | 2630 |

| Clipping height | 1-11cm | |||

| Effective cropping width | 1700mm | 2000mm | 2300mm | 2600mm |

| Effective cutting length | Automatic feeding unlimited length | |||

| Automatic spreading length | 16.8m spreading table(total working length 24m) | |||

| Land size | 35000*2600*1600mm (L*W*H) | 35500*2900*1600mm (L*W*H) | 40000*3300*1600mm (L*W*H) | 40300*3600*1600mm (L*W*H) |

| Way of transporting the knife | Reciprocating vibrating knife transport | |||

| Cutting speed | 0-60m/min | |||

| Cuttingknife grinding | Double wheel counter-rotating grinding | |||

| Adsorption method | Frequency conversion vacuum constant pressure control mode | |||

| Safety devices | Automatic induction | |||

| voltage | Three-phase AC380V/50Hz/25KW | |||

| Operate computer | Ordinary computer,Windows7 | |||

| Operation panel | Touch control panel | |||

| Clipping parameters | Input LAN,USB | |||

| Device weight | 4500kg | |||

| Other functions | Mobile cutting device, automatic feeding device,pattern scanning,adsorption bed | |||

| Operating system | Suppors the overall rotation of the nesting chart, knife-edge conversion,single-piece recutting, one-key deletion of overlapping areas (supports removal of repeated lines),residual cloth cutting | |||

| Main machines and accessories | 1.Automatic multi-layer cutting bed 2.Automatic cloth spreading machine 3. Air floatation table | |||

Multi Layer Fabric Cutting Machine Advanced

Multi-layer fabric cutting machines are designed to handle multiple layers of fabric stacked on top of each other. The cutting capacity can vary depending on the machine model and the thickness of the fabric, but it can typically range from several layers up to dozens of layers.

These machines often feature a conveyor or table system for feeding and positioning the fabric layers. The system can include a motorized conveyor belt or an adjustable cutting table that enables smooth and precise movement of the fabric during the cutting process.

Multi-layer fabric cutting machines employ various cutting tools to cut through the stacked fabric layers. Common cutting tools include rotary blades, straight blades, or oscillating blades. The choice of cutting tool depends on the specific fabric type, thickness, and desired cutting precision.

These machines are designed to provide high cutting accuracy and consistency across all layers of fabric. They incorporate features such as precise cutting guides, automated cutting paths, and advanced control systems to ensure uniform cuts throughout the stacked layers.

Multi-layer fabric cutting machines are optimized for speed and efficiency. They can cut through multiple layers of fabric in a single pass, significantly reducing production time and increasing productivity compared to cutting individual layers separately.

Textile and Garment Manufacturing: Cutting fabric pieces for clothing, accessories, and fashion items.

Automotive Industry: Producing upholstery and interior components.

Furniture Manufacturing: Cutting fabric, leather, and foam for furniture upholstery.

Footwear Industry: Cutting materials for shoe production.

Medical Textiles: Producing fabric components for medical supplies such as bandages and gowns.

Packaging Industry: Cutting foam and other materials for protective packaging solutions.

Multi-layer fabric cutting machine is more suitable for massive orders of big shape patterns like soft furniture and garment, while the die cutting machine can better deal with bulk orders of small shape patterns like shoe uppers, hats, and gloves.

When using industrial fabric cutting machines, you want your device to produce as much plain fabric per day as possible. The higher the production, the higher the efficiency.

However, the output of this depends on the type of industrial fabric cutting machine.

In this aspect, the multi-layer fabric cutting machine and the die cutting machine have a higher production capacity due to the multi-layer cutting method.

| Product number | 1725 | 2030 | 2330 | 2630 |

| Clipping height | 1-11cm | |||

| Effective cropping width | 1700mm | 2000mm | 2300mm | 2600mm |

| Effective cutting length | Automatic feeding unlimited length | |||

| Automatic spreading length | 16.8m spreading table(total working length 24m) | |||

| Land size | 35000*2600*1600mm (L*W*H) | 35500*2900*1600mm (L*W*H) | 40000*3300*1600mm (L*W*H) | 40300*3600*1600mm (L*W*H) |

| Way of transporting the knife | Reciprocating vibrating knife transport | |||

| Cutting speed | 0-60m/min | |||

| Cuttingknife grinding | Double wheel counter-rotating grinding | |||

| Adsorption method | Frequency conversion vacuum constant pressure control mode | |||

| Safety devices | Automatic induction | |||

| voltage | Three-phase AC380V/50Hz/25KW | |||

| Operate computer | Ordinary computer,Windows7 | |||

| Operation panel | Touch control panel | |||

| Clipping parameters | Input LAN,USB | |||

| Device weight | 4500kg | |||

| Other functions | Mobile cutting device, automatic feeding device,pattern scanning,adsorption bed | |||

| Operating system | Suppors the overall rotation of the nesting chart, knife-edge conversion,single-piece recutting, one-key deletion of overlapping areas (supports removal of repeated lines),residual cloth cutting | |||

| Main machines and accessories | 1.Automatic multi-layer cutting bed 2.Automatic cloth spreading machine 3. Air floatation table | |||

Multi Layer Fabric Cutting Machine Advanced

Multi-layer fabric cutting machines are designed to handle multiple layers of fabric stacked on top of each other. The cutting capacity can vary depending on the machine model and the thickness of the fabric, but it can typically range from several layers up to dozens of layers.

These machines often feature a conveyor or table system for feeding and positioning the fabric layers. The system can include a motorized conveyor belt or an adjustable cutting table that enables smooth and precise movement of the fabric during the cutting process.

Multi-layer fabric cutting machines employ various cutting tools to cut through the stacked fabric layers. Common cutting tools include rotary blades, straight blades, or oscillating blades. The choice of cutting tool depends on the specific fabric type, thickness, and desired cutting precision.

These machines are designed to provide high cutting accuracy and consistency across all layers of fabric. They incorporate features such as precise cutting guides, automated cutting paths, and advanced control systems to ensure uniform cuts throughout the stacked layers.

Multi-layer fabric cutting machines are optimized for speed and efficiency. They can cut through multiple layers of fabric in a single pass, significantly reducing production time and increasing productivity compared to cutting individual layers separately.

Textile and Garment Manufacturing: Cutting fabric pieces for clothing, accessories, and fashion items.

Automotive Industry: Producing upholstery and interior components.

Furniture Manufacturing: Cutting fabric, leather, and foam for furniture upholstery.

Footwear Industry: Cutting materials for shoe production.

Medical Textiles: Producing fabric components for medical supplies such as bandages and gowns.

Packaging Industry: Cutting foam and other materials for protective packaging solutions.