Views: 11 Author: Site Editor Publish Time: 2022-03-19 Origin: Site

Edge Banding Machine For Woodworking Description:

IGOLDENCNC Edge Banding Machines offer perfect edges for discerning wood manufacturers of all sizes. We provides first-class edge processing solutions for a wide range of processes and materials with extreme accuracy and precision.

1、Pre-milling unit

The premilling station comes with two 1.1kw high frequency motors with counter rotating 60mm diameter diamond cutterheads which ensure perfect trimming of up to 60mm thick panels.

Gluing Unit

2、1.5 kg capacity Teflon coated glue pot is suitable for both PUR and EVA glue. The precise glue quantity control allows for an optimal glue amount to be applied to the edge of the panel. Equipped with a quick change system for cleaning or multiple glue pots (on request). The automatic cleaning cycle cleans the glue spreader roll.

3、Tape Feeding Device & Strip Feed

Capable of feeding both coil and strips with the strip feed magazine. This automatic edge infeed device is designed for fast change over between coil and solid wood edge up to 6 mm.

4、Pressure Zone

The rotating pressure roller section guarantees an optimal glue point. This heavy-duty pressure zone comes with 3 pcs steel rollers which can be quickly set to apply your various edge thickness. The pressure section ensures the proper bond of the edge to the substrate.Dust Collecting Box

Collects the trimming from the scraping unit in a separate storage comportment so they are not collected in to the dust collector where they could impede the impeller fan.

4、End Trimming Unit

Precision dual motor high frequency end cutting units travel on precision linear guides for flush end trimming of the panel. Motors can be set to straight or chamfer 15° automatically from the control panel.

5、Top & Bottom Trimming Unit

The innovative design of this unit allows for precise results regardless of the type of edge and panel you are using. The two high frequency motors can be tilted for bevel 15° or straight cutting. The multi-functional cutters can be set up for flush trimming, bevel trimming, or radius trimming.

6、Corner Rounding Unit

The innovative design of this unit allows you to get a precision end rounding on your panel every time without cutter marks. Optimum corner rounding without adjustment or set-up, resulting from the combination of a diamond tool and tracer roller. Capable of corner rounding workpieces up to 60mm in thickness.

7、Radius Scrap Unit

This unit with its user-friendly design is able to eliminate any knife marks left on the edge after profiling on the top & bottom trimmers. It can be easily excluded when processing edges not requiring the radius scraper

What is the details of our Edge Banding Machine for wood?

1. Glue pot is casted as a whole part. So it won't broken.

2. Glue shaft is patent design, CNC processing, to guarantee the glue output and daub evenly.

3. All edge banding parts adopt CNC processing, error control within 0.017 mm.

4. End cutting tidily, docking closely between the cutting end, basically no gap.

5. Our bearings are made in Japan.

Pneumatic element: Airtac

Electric device: Omron , TECO , Schneider

Advantages Of china woodworking full automatic mdf board cabinet pvc edge banding machine edge bander:

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used for positioned location assured the panel materials processing accuracy in a very high level.

8.Secondary Dust Exhaust System, mainly used for sawdust collection during processing period, to keep the material smooth and clean.

9.The machine adopts the devices of sound insulation, controlling of dust, platform frame Micro adjustment by manual operation.

requires only 15 minutes to reach operating temperature. The tool free quick change system guarantees quick cleaning and change over times when changing the glue or colour. The synchronised, fine adjustable glue roller ensures the right application amount

of glue.

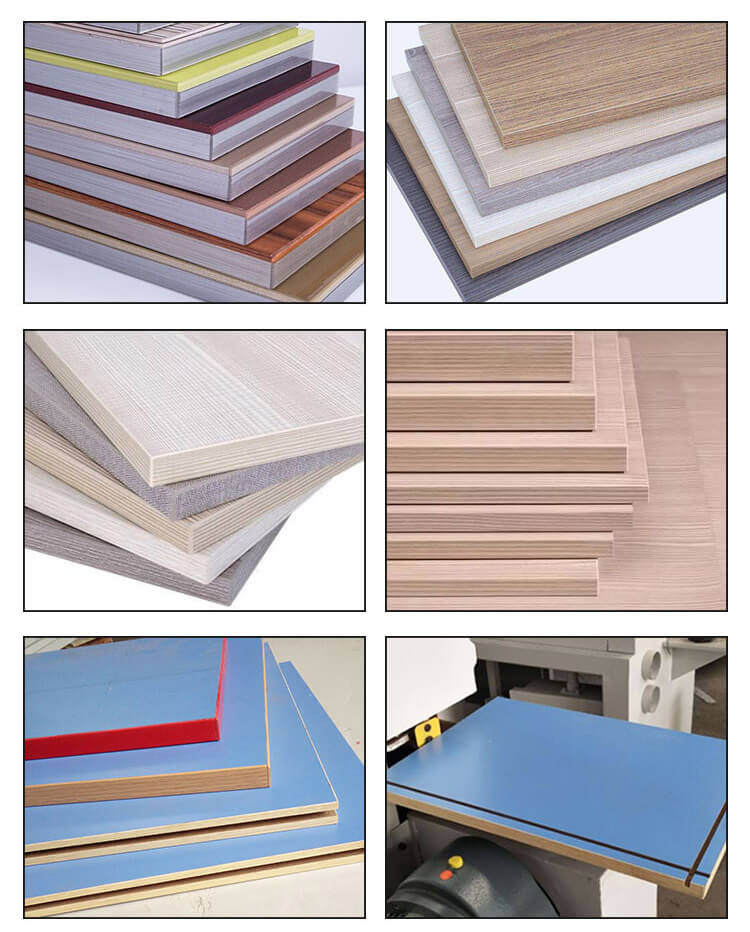

Application of Edge Banding Machine for sale:

The automatic linear edge banding machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc.