Views: 9 Author: Site Editor Publish Time: 2022-04-16 Origin: Site

The jewellery spot welding machine can realize spot welding, butt welding, stitch welding, seal welding, seam welding and penetration welding, etc., and can weld complex trajectories such as plane, circle and arc.

Weld strength: The laser weld is narrow with an excellent depth-to-width ratio and higher strength.

Heat affected zone: The heat affected zone is limited, and due to rapid cooling, the surrounding material is not annealed.

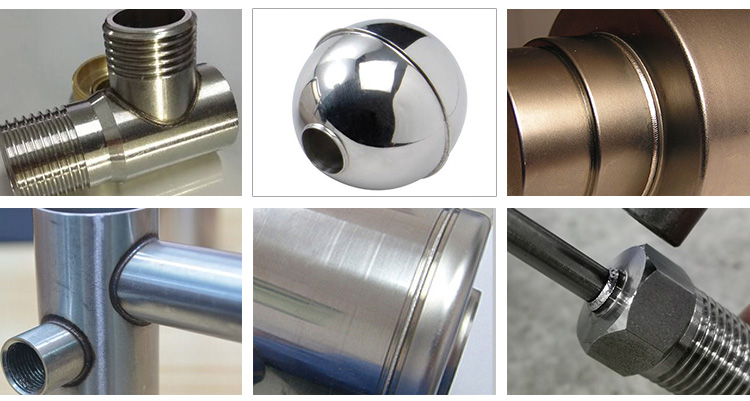

Metals: Lasers successfully weld carbon steel, high strength steel, stainless steel, titanium, aluminum, and precious metals as well as dissimilar materials.

Precision work: The small, tightly controlled laser beam permits accurate micro-welding of miniature components.

Deformation: Parts have minimul deformity or shrink.

No contact: No physical contact between the material and laser head.

One sided welding: Laser welding can replace spot welding requiring access from one side only.

Scrap: 1kw laser welder is controllable and generates low volumes of scrap.

Spot welding devices have become quite popular on the market and are indeed now indispensable features in many goldsmith studios and production firms. Instead of elaborate soldering on the item of jewelry and heating up the entire jewelry metal, the advantage of electric spot welding lies in the targeted application, enabled by the light arc. The precision of the welding, the simple application and the time savings in assembly to repair of jewelry items enable efficient working.

How does jewellery spot welding machine work?

Welding by laser beam is basically very simple: Two precisely cut sheets are held together. The laser melts the edges of the sheet metal. The melt flows into each other - and the joint is complete.

Due to the high welding speed and small heat affected zone of laser welding, the overheating phenomenon and the adverse effect of the large linear expansion coefficient during welding of stainless steel are alleviated, and the welding seam has no defects such as pores and inclusions. Welding stainless steel sheets with low-power lasers can obtain joints with good appearance and smooth and beautiful welds.

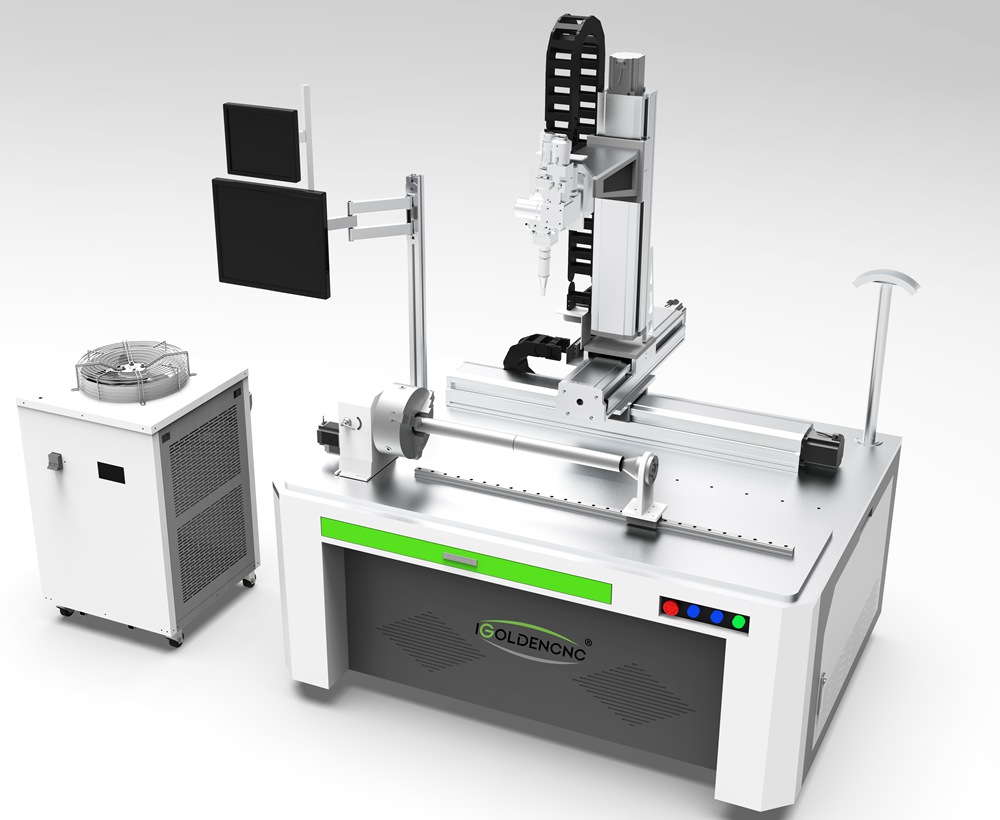

Automatic Fiber Laser Welding Machine Application: