Views: 8 Author: Site Editor Publish Time: 2021-12-22 Origin: Site

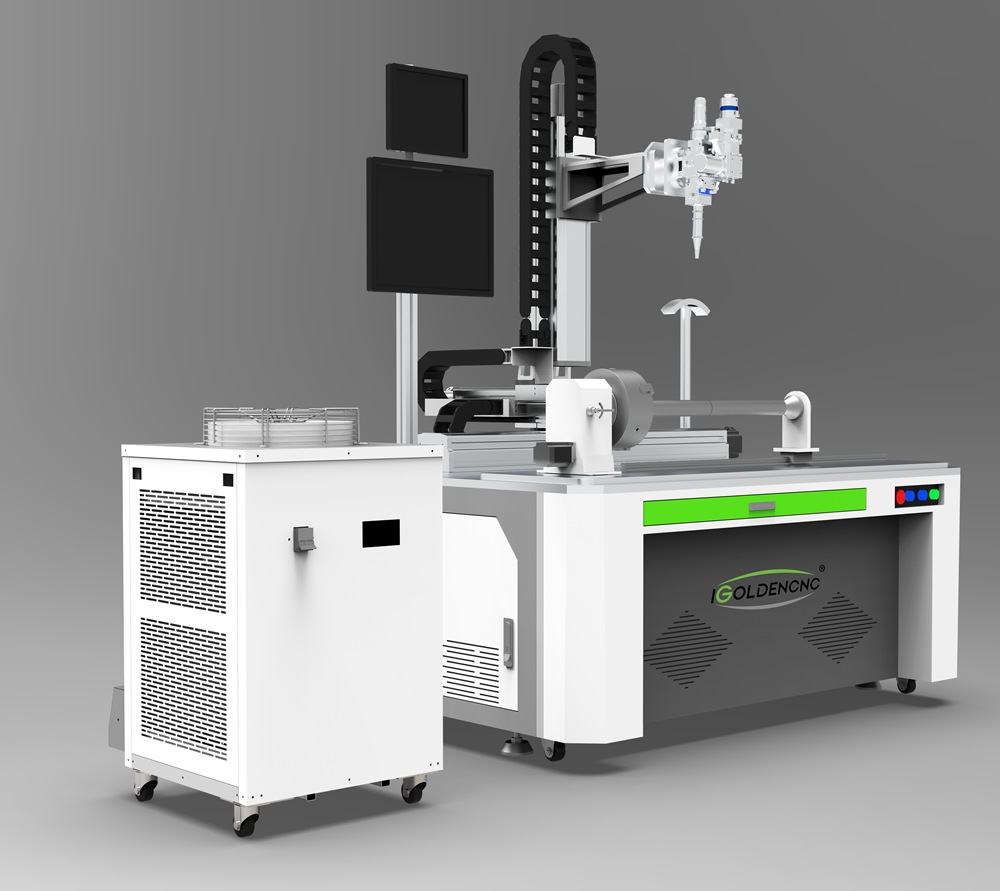

For production workshops engaged in small-scale processing or non-large-scale welding, laser welding machine are the best choice, occupying small space and diversifying welding products. The 1500W Fiber Laser Automatic Welding Machine uses a handheld welding gun to replace the previously fixed optical path, subverting the previous working mode of the laser welding machine. This mode of operation is not only convenient for welding moulds, advertising words, kitchenware and other products, but also for outdoor laser welding.

1. Even tiny workpieces can be processed. In addition, welding can be performed through the walls of transparent materials.

2. Multiple simultaneous or time-sharing welding is possible over long distances and in areas that are difficult to reach by conventional methods via optical fiber.

3. Non-contact processing without pressure and surface treatment of the workpiece.

4. Easy to be mounted on automatic machines and robotic devices.

5. Direct welding of conductors with insulation, and welding of dissimilar metals with widely differing properties

6. Small welding joints, high energy density, and suitable for high-speed processing.

7. No need for filler metal, no need for vacuum environment (can be done directly in the air), no danger of X-rays in the air like electron beam.

8. No processing noise, no pollution to the environment.

9. Short-time welding, not only to the outside world without heat, but also to the material itself heat deformation and heat-affected zone is small, especially suitable for processing high melting point, high hardness, special materials.

10. Compared with the contact welding process. No electrodes, tools, and other wear and tear consumption.

Compared with traditional welding methods, the precise control of Automatic Fiber Laser Welding Machine provides users with a number of advantages:

Faster welding speed: Laser welding is a very fast technique. Depending on the type and power of laser used, thin section materials can be welded at speeds of many metres a minute.

Weld strength: The laser weld is narrow with an excellent depth-to-width ratio and higher strength.

Heat affected zone: The heat affected zone is limited, and due to rapid cooling, the surrounding material is not annealed.

Precision work: The small, tightly controlled laser beam permits accurate micro-welding of miniature components.

Deformation: Parts have minimal deformity or shrink.

No contact: No physical contact between the material and laser head.

One sided welding: Laser welding can replace spot welding requiring access from one side only.

Scrap: Laser welding is controllable and generates low volumes of scrap.

Suitable for a range metal materials and thicknesses: With lasers, many different materials can be welded or joined, including steels, stainless steels, Al, Ti and Ni alloys. Furthermore, taking the example of steels, the thickness of the material that can be welded can be anything from under a millimetre to around 30mm , depending on the type and power of laser used.