Views: 12 Author: Site Editor Publish Time: 2022-01-19 Origin: Site

This Wood CNC machine for beginners is equipped with Fuling frequency converter. This inverter has stable performance, rich combination of functions, high-performance vector control technology, low-speed and high-torque output, good dynamic characteristics and super overload capacity. The machine is also equipped with an automatic oil lubrication device. Just set the interval time and oil filling time, the machine can automatically lubricate the guide rail and the lead screw according to the system setting, which is very convenient.

Wood CNC machine Features:

1) Designed with rotary device, it can process the cylinder wood carving patterns, furniture legs, escalators, etc..

2) With the heavy duty thicker and bigger welded steel tube frame, it makes the machine work more stably.

3) Adopting DSPB18 control system and servo motor driver system, which ensure the machine with a longer service life.

Applications Materials

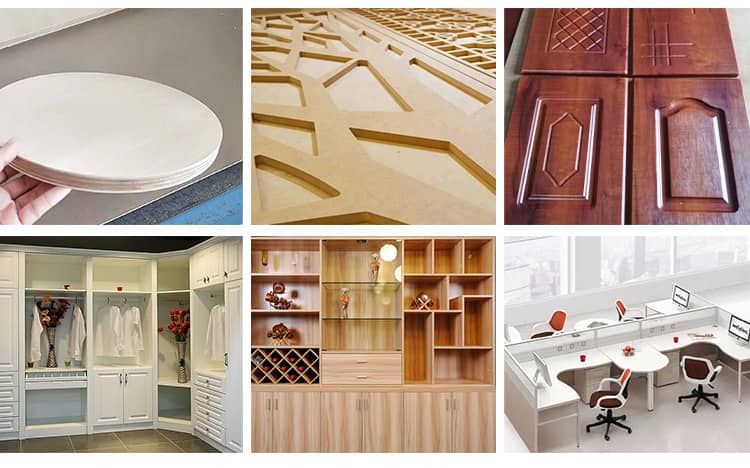

1. Woodworking: Wooden door and furniture, windows, tables and chairs, cabinets and panels, 3D wave plate, MDF, computer desk,

Musical instruments, etc

2. Advertising: Billboard, logo, sign, 3D characters cutting, acrylic cutting, LED/neon channel, literal- hole cut, lightbox mold, stamp, mould

3. Die industry: Copper sculpture, aluminum engrave, metal molds, plastic sheeting, PVC, etc

Specification:

Super quality 9KW Air cooling Auto-tool changer spindle.

linear guide rail keep high working precision

Famous servo motor and driver ensures machine to run with fast speed and low noise.

With 12 pieces auto-tool changer and Auto tool sensor.

Vacuum table and vortex vacuum pump, and 3.0kw dust collector.

Taiwan LNC ATC controlling system, which can change tools alternatively, tool sensor to compensate the tolerance of tool length.

High accuracy, long service time, steady movement and good starting performance, great torque, fulfilling the advantage of working with fast and high efficiency.

There are a number of components to plug in before we can get started:

1. Power on the Router controller box near the wall by turning the ON/OFF swift.

2. Then press the green start button to start the remote controller.

3. Turn on the dustcollector – (remember to check the dust bags).

4. Start the vacuum table by pushing the white button.

Step 2: Choose End Mill - Intro

There are a number of different blades to choose from when conducting a project on a CNC router machine. The CNC router bits we are limited to using are known as end mills, and they take on a number of different shapes and sizes. We'll give a brief crash-course on end mills here. Following are the aspects we hope you will fully understand between completing this course and embarking on your first CNC routing project:

1. Number of flutes.

2. End mill shape: Flat vs. Ball nose vs. V-bits.

3. Sizing.

Step 3: Choose End Mill - Flutes

ake a look at the first picture included in this step and see if you can notice a difference between the two bits displayed. In case you can't tell, the CNC bit on the right has four edges, where as the CNC bit on the left only has two edges. These edges are called as flutes and each serves its own purpose in a CNC project. What is the difference between them? We like to describe the difference between four-flute and two-flute end mills as the similar difference between a wood saw and a hacksaw. A wood saw has much fewer and larger teeth than a hack saw - making it ideal to cut softer materials like wood. A hack saw has fine teeth close together,

Step 4 Change Blade or End MillIf the end mill you want already is in the CNC machine when you approach. Then just check for tightness the following instructions:

Step 5: Set Up Workpiece on Table• When your are planing to cut your plate, it's important to check that all the 4 vacuum zones (under the MDF), if there are rubber strips to be placed all around the zones edges, to ensure the strangth af the vacuum, the strength of the vacuum determines how much of the air pressure is actually going to work hold down your workpieces.

Step 6: Set Up X and Y Axis

There is two difference ways you can set you can set up the Z axis:

Step 7: Load File for CNC Router Machine

Step 8: Safety Guide to CNC Router Machine