Views: 6 Author: Site Editor Publish Time: 2021-11-15 Origin: Site

Welding fiber laser is a welding technology used to create a strong joint between several metal components with fiber laser. Fiber laser produces a beam of high-intensity that is concentrated into one spot. This concentrated heat source enables fine, deep welding with high welding speed.Handheld laser welding machine has the advantages of simple operation, beautiful weld seam, fast welding speed, and no consumables. It can be used for welding various metals sheets and tubes: such as stainless steel plates, iron plates, galvanized plates and CS plates, aluminum plates, brass plates, other metal sheets and tubes.

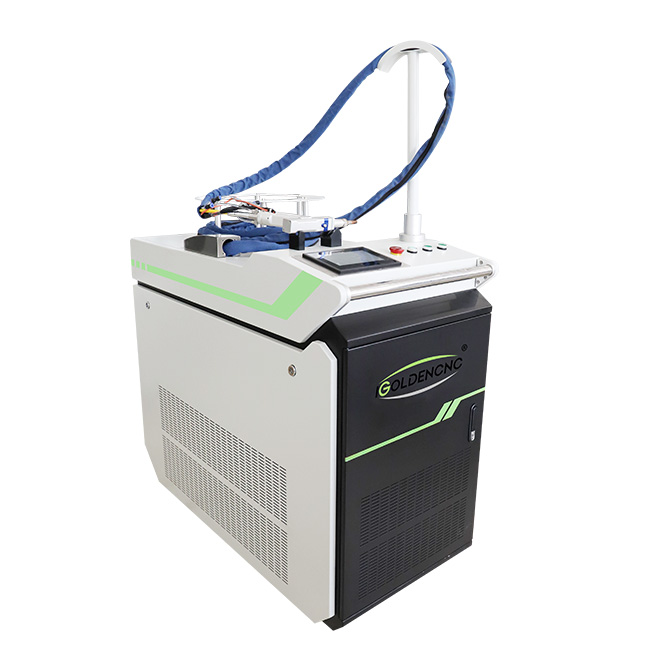

1.portable laser welder, fixed optical path, flexible and convenient, long-distance laser welding

2.Hand-held welding head is light and flexible, meeting a variety of angles, welding in multiple positions

3.Infrared positioning, the welding position is more accurate, ensuring a more beautiful weld

4.Fast welding speed, easy operation, reduced time and cost

5.Laser welding depth is large, welding is strong, suitable for all kinds of complicated welding

Features of welding fiber laser:

1) High Efficiency

The welding speed of laser welding machine is twice of traditional welding method.

2) High Quality

The weld seam is smooth. There is no need to polish the weld seam, saving time and manpower.

3) Low Cost

80% to 90% power savings, processing costs are reduced by 30%.

4) Flexible Operation

Can operate it without experience.

How Does welding fiber laser Work?

The pump source supplies the medium with energy. It stimulates the laser in a way that the electrons in the molecules are temporarily lifted to a higher energy state.

The electrons in the stimulated state cannot remain there as they drop drastically to a lower energy level.

They give off a photon as they lose the excess energy they get from the pump. It’s known as impromptu emission and the photons created by this process are the seed for the production of a laser.

The photons are given off by the impromptu discharge. Lastly, they hit other electrons present in the elevated energy states. When an approaching photon “knocks” the electron from the stimulated state to a lower level of energy, another photon is formed. These photons are consistent. It implies that they’re in phase, has a similar wavelength, and are moving in the same direction. The procedure is referred to as stimulated emission.

Photons are given off in every direction. Nonetheless, some of them move lengthwise to hit the vibrator mirrors, which bounce back via the medium. The vibrator mirrors determine the preferred amplification direction for the exciting discharge. There has to be a greater atoms percentage in the stimulated form than the lower energy levels for amplification to take place. This population inversion of excess atoms in the stimulated state causes several conditions needed for the generation of a laser.

The laser’s concentration spot is directed towards the workpiece surface which you’re welding. The concentration of light energy transforms into heat (thermal) energy at the surface. The heat makes the material thaw. It advances via the surface through a procedure known as surface conductivity. The gleam level of energy stays below the evaporation temperature of the workpiece material. The perfect thickness of the materials you’re welding should be 20mm. The energy of the laser is concentrated. It’s a benefit if you’re working with materials with high thermal conductivity.